What are the cement clinkers? How many cement clinker processing equipment are there? According to proper proportion made limestone and clay, iron into raw material, burn till the partial or complete fusion, and semi-finished products obtained after cooling. In the cement industry, the most commonly used of the main chemical composition of portland cement clinker are calcium oxide, silicon dioxide and a small amount of alumina and iron oxide. The main mineral composition is tricalcium silicate, dicalcium silicate, tricalcium aluminate, and iron and aluminum acid calcium. Serve Portland cement common ground portland cement clinker add appropriate amount of gypsum.

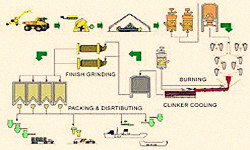

The cement clinker equipment is popular in the traded of mining, building materials, chemical engineering and metallurgy for size reduction, dispersion, or specialized needs, powder generation and processing for industrial process. Following are the crushing processing and raw material advance homogenization for cement clinker.

The cement clinker equipment is popular in the traded of mining, building materials, chemical engineering and metallurgy for size reduction, dispersion, or specialized needs, powder generation and processing for industrial process. Following are the crushing processing and raw material advance homogenization for cement clinker.

In cement production process, most of the raw materials need to be broken, such as limestone, clay, iron ore and coal. Limestone to produce the maximum amount of cement raw materials, larger particle size, high hardness after mining limestone crushing occupies a more important position in the cement plant materials broken. The crushing process than the process of grinding economic and convenient, reasonable selection of crushing equipment and grinding equipment is very important. Before the material enters the grinding equipment, it is possible for the bulk material is crushed to a fine, uniform particle size, in order to reduce the load on the grinding equipment, to improve the yield of Fen machine. Material crushing to reduce the phenomenon of the separation of materials of different particle size in the transport and storage process, something in the uniform composition of raw material, to improve the accuracy of the ingredients.

Raw material pre-homogenizing technology is in the retention of the raw materials, to take the process to use the scientific stacker reclaimer technology, raw materials are initially raw material yard along with storage and homogenization function. In the stockpiling by the feedstock prehomogenization basic principle is stoker the incoming raw material continuously in a certain way piled as much as possible parallel to each other, stacked vertically, and the material layer of the same thickness. Reclaimer in the direction perpendicular to the material layer, as much as possible at the same time cut all the material layer, in turn cut until you get finished tile straight to take

Cement clinker equipment

Cement clinker equipment manufacturer supply you crushing machine and grinding mill for the cement clinker process, the cement manufacturers purchasing clinker grind it as an addition to their own clinker at their cement plants. Manufacturers also ship clinker to grinding plants in areas where cement-making raw materials are not available.

Cement clinker equipment manufacturer supply you crushing machine and grinding mill for the cement clinker process, the cement manufacturers purchasing clinker grind it as an addition to their own clinker at their cement plants. Manufacturers also ship clinker to grinding plants in areas where cement-making raw materials are not available.

Cement clinker grinding machine is your primary choice, we supply you raymond mill, and the fineness of the finished product can be adjusted from 100 to 425 mesh (35micron), we also offer SCM ultrafine mill, the ultrafine mill can be installed directly as the only powder grinding equipment in the whole grinding plant or it can be used as further-grinding machine after ball mill grinding or coarse powder grinding.

Liming Heavy Industry group have more then 100 types of crushing and grinding equipment, which is suitable for processing cement clicker, and Liming Heavy Industry will be able to provide a unique end-to-end solution including cement clinker processing equipment, products maintenances, after sale service, etc. Welcome to consult for more information.