Stone crushing production line rational allocation is an important factor for the effective functioning of production line, so how to choose the right equipment, and a reasonable allocation of the production line has become extremely important, Liming Heavy Industry can give you with complete technical support in stone crushing plant configuration.

As we all know, reasonable crusher and mill model configuration, a reasonable mix of energy conservation, the most effective measures to promote the production. Now introduce reasonable configuration gravel production line, sand production line, sand making production line, crusher equipment. It should pay attention to the problem required such large sets of crushing facilities, reasonable the configuration will greatly reduce costs, achieve high yield, low-power production, truly the best use.

As we all know, reasonable crusher and mill model configuration, a reasonable mix of energy conservation, the most effective measures to promote the production. Now introduce reasonable configuration gravel production line, sand production line, sand making production line, crusher equipment. It should pay attention to the problem required such large sets of crushing facilities, reasonable the configuration will greatly reduce costs, achieve high yield, low-power production, truly the best use.

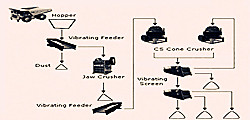

Gravel production line is dedicated equipment for process construction sand and stone. It can increase sand making energy-efficient than the traditional by 50%. Gravel production line can processing a variety of rock, sand and gravel, river pebbles chime in various size building sand, sandy uniform particle size, high compressive strength, than natural sand, sand the ordinary hammer play sand production more in line with the construction requirements that can enhance the quality of construction. Respectively to artificial gravel production line via a feeder, jaw crusher, crushing (sand making machine, Impact Crusher) the needs of a variety of specifications through the vibrating screen of gravel, sand through efficient sand washing machine after you demand the finished sand, sand production line equipment combination of vibrating feeder, jaw crusher, sand making machine, vibrating screen and tape transfer machine.

In different sand production, gravel production line is no uniform standard, with stone production line equipment according to production requirements, production processes, material hardness.

In different sand production, gravel production line is no uniform standard, with stone production line equipment according to production requirements, production processes, material hardness.

When the hardness of the material does not exceed 320Mpa, it is most appropriate use of the two stages stone production line process. Such as granite and basalt are applicable to use the two stages crushing process. Production processes: stone sent to jaw crusher by vibrating feeder for the first time broken, material transported by conveyor to secondary crusher after crushed in jaw crusher, crusher equipment for this process can choose impact crusher, hammer crusher, secondary impact crusher. After the second crushing, materials were sent into vibration sieve and then it can get desirable stones.

When the material hardness is not more than 150Mpa, for this hardness of the material, it no need to use secondary crushing. General molding, then finished vibrating screen. Equipment: vibrating feeder – efficient compound crusher (Combo crusher, the large pieces of material through a unique design, time to achieve the desired particle size is generally hammer crusher) – vibrating screen – finished stone materials, intermediate transfer belt conveyor. Choose different materials of different hardness gravel production line process can save costs and reduce unnecessary waste.