When layout the crushing plant in mine, crushing and screening system should be designed co-ordination with mine design, and the system also should choose a reliable technology, energy saving, cost-effective management and maintenance to facilitate the process and equipment.

Crushing and screening system design should determine the process and equipment selection, construction, installation, operation, maintenance, access requirements should meet. Position the crushing workshop to determine the location should be determined in accordance

Crushing and screening system design should determine the process and equipment selection, construction, installation, operation, maintenance, access requirements should meet. Position the crushing workshop to determine the location should be determined in accordance

with the cement raw material mining conditions, external transport conditions, the relationship of the mine and plant site location and site engineering geological conditions. Broken system should be determined according to the mine mining technology, mining scale and speed of the descending part of the scale of investment in its category. Broken system near mine should be arranged in blasting security cordon outside; flying stone, the Rolling Stones, blasting seismic waves protective measures should be taken to prevent broken system layout within the boundaries of the mine blasting safety. The production capacity of the crushing system equipment selection should be based on the annual ore production capacity, the annual number of working days, the the broken system working class system and the transport uneven coefficient determined.

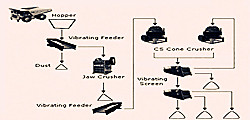

Taking a multi-stage crushing, the production capacity of multi-stage crushing system should match each other. Crusher equipment selection should be based on adaptability to raw materials and abrasive test materials and material mechanical properties. Crushing number of segments should be chosen according to the nature of the ore material, after crushing the material size and product size requirements determined. The limestone crushing advised to use a single-stage crushing, jaw crusher is recommended when using a multi-stage crushing system, a crusher crusher manufacturer Liming Heavy Industry Science and Technology, gyratory crusher, tertiary crusher advised to use a hammer crusher , Impact crusher or cone crusher, etc.; clay, shale should use teeth roll crusher.

Crusher discharge port should adopt the belt conveyor discharge belt conveyor according to broadband, low-speed configuration, its width should crusher discharge port size, production capacity to adapt. Limestone, sandstone, clay, cement raw material crushing plant dust removal device should be set, and the amount of dust wind should be based on the specifications of the crusher, structural features, broken determined than the material properties.

Liming Heavy Industry’s professional team will provide you best solution and technical support. We will do our best to service global customer, 24 hours online.