Rotary dryer is mainly used to dry materials with a certain humidity in the ore dressing, building materials, metallurgy, chemical and other departments. The size of the dried material is generally not more than 50mm. The series of dryers produced by Liming Heavy Industry are widely used for drying iron oxide scale, sludge, coke, pig iron scrap, copper concentrate, silicon carbide powder, rare earth ore, mercury ore powder, tin ore powder, cobalt ore powder, nickel ore powder, manganese ore powder, gypsum powder, bentonite, kaolin, lead concentrate, petroleum coke, gold ore powder, steel slag, water slag, fluorite ore, sea sand, river sand and other materials.

Rotary Dryer Type

According to the structure, the rotary dryer can be divided into a single-cylinder dryer and a multi-cylinder dryer. The multi-cylinder dryer includes a double-cylinder dryer and a three-cylinder dryer.

According to the heat transfer method, the dryer can be divided into a direct heat transfer dryer and an indirect heat transfer dryer.

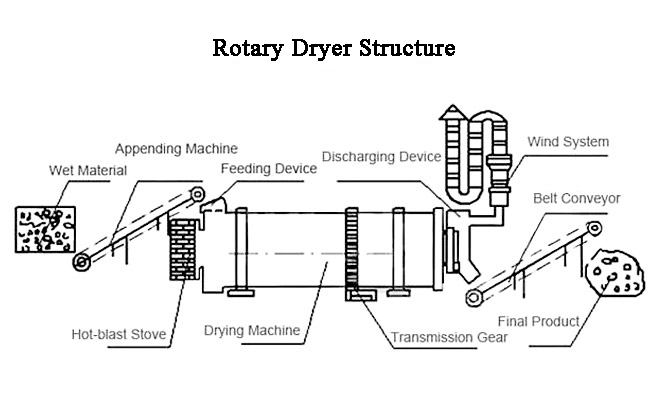

Rotary Dryer Structure

The rotary dryer is mainly composed of a cylinder, a supporting device, a transmission device and ancillary equipment.

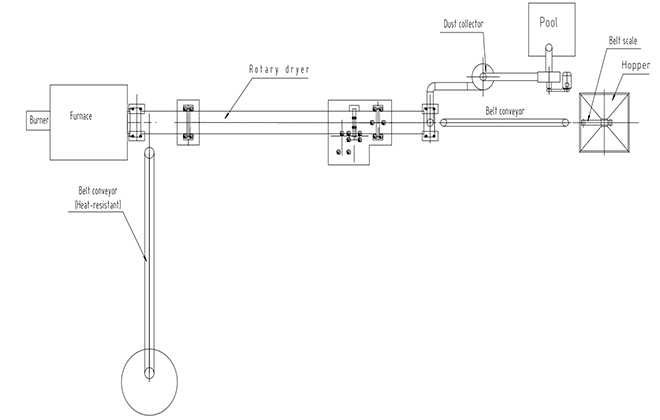

Rotary Dryer Working Principle

During the process of the material entering the cylinder and moving along the axis of the cylinder, on the one hand, material is heated by the cylinder, and on the other hand, it is exchanged with hot air during the process of being lifted by the lifting plate. The moisture of the wet material is evaporated during the heating process, and the moisture content is gradually reduced.

Rotary Dryer Heat Source

The heat source used by the dryer is natural gas, coal, electrical energy, etc. At the same time, the selection of the heat source of the dryer also affects the operating cost of the dryer. When selecting a heat source for a dryer, you must select a suitable heat source in accordance with the local conditions, the safety of the heat source, environmental requirements, etc.

Heat Transfer Method

1.Downstream

2.Countercurrent

Click “Online Customer Service” for consultation, we will provide you with free production equipment solutions and quotes.