The government and society pay more and more attention to the effective recycling of construction waste. With customized crushing and grinding production lines, more than 95% of construction waste can be reused as raw materials for various building materials, which has great economic value and social value. Environmental value.

(1) Manufacturing concrete recycled aggregate

Crushing waste masonry, cement concrete, etc. into recycled aggregates, which can replace ordinary sand and gravel materials for roadbed construction or concrete preparation.

(2) Manufacturing recycled non-burning bricks

After the waste bricks are crushed and pulverized, 150# and 175# bricks meeting the requirements of GB5101-85 “Standard for Sintered Ordinary Bricks” can be produced, and the burning and steaming process can be saved.

(3) Recycled non-burning masonry cement

After the waste brick powder is ground, no firing process is required, and 175# and 275# masonry cement meeting the GB/T3183 standard can be produced.

(4) Other new building materials products

After being crushed and ground, construction waste can also be made into new wall material products such as concrete standard bricks and concrete porous bricks, as well as concrete pavement brick products such as pavement bricks, permeable bricks, and curb stones.

(5) Landfill hills

Construction waste with no recycling value can also be used as backfill material to build landscape rockery and gardens after being broken.

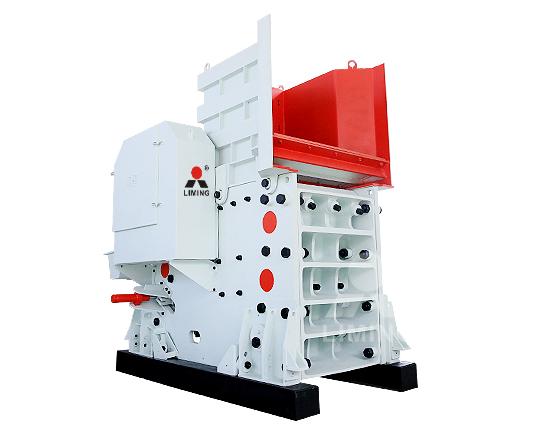

Required equipment:

Jaw Crusher

It is widely used for medium-size crushing of ore and bulk materials in mining, smelting, building materials, highways, railways, water conservancy and chemical industries.

MTM Medium Speed T-Shaped Pulverizer

It is widely used in metal and non-metal mines, cement plants, construction, sand and stone metallurgy and other industries.